95 Winchester with custom quarter rib and express sights

By: Fred Zeglin AGI Instructor, Author, Lassen College Gunsmithing Graduate and Cartridge Designer

When I graduated from gunsmithing school, I went to work in a shop that exposed me to many custom features and services that could be offered to our clients. High on that list were custom scope mounts and sights. Such work is really not difficult and because many shops neglect to offer such work, it’s profitable and attracts new clients once the word gets out that you offer the services.

It seems like every shop offers Williams® ramps and sights or their equivalent. They might even carry the popular peep sights made by the same company. Most shops do not realize the value of offering a wider variety of sights, or at least something different than the shop down the street.

The first custom scope mounts I made while working for that shop were designed to use Conetrol® rings. We had a jig that bolted to the table of the mill. It held a blank of low carbon ground stock. A boring head was used to precisely cut the contour on the bottom of the mount. Bases for Conetrol® are simple to make because all they require to hold the ring is a round hole for the base of the ring and a cross hole threaded to accept the cone point screws that give the company it’s name.

We fancied those bases up by using corner rounding mill cutters to sculpt the edges; that set them apart from factory bases. We could also make them to fit any barrel or receiver. These simple bases opened my eyes to the many possibilities. I still use Conetrol® rings and bases for some specialty installations. With all that in mind, I thought it would be fun and interesting to look at a few custom sight and scope installations.

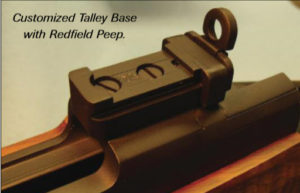

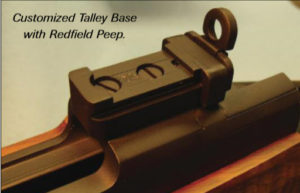

If you’ve been shooting for more than twenty years you might have seen these old peep sights. Redfield® used to offer these as a back up sight option on their scope bases. See the Redfield fold-down peep attached to base in the photo below.

They were dropped from production many years ago. However, there are some shooters who still favor them because they are so small and can be mounted very low on the gun. Their design keeps them out of the way when unneeded and minimizes the front sight height as well. The peep is a ghost ring style and folds down when not in use. They can be found at gun shows and, from time to time, on an auction site. You will probably have to buy the whole scope base to get them.

Adapting the Talley base for this gun required adding a piece to the base to accept the peep. I would probably have machined a custom base but the time limits made a modified base a necessity. The tight space constraints of the two piece Talley bases made this approach the most sensible.

When doing such work be sure to consider whether the bolt will open and close without touching the sight. It may be necessary to mock up the parts to be sure they will all clear.

In this case the action is a Dakota 76. First I milled the back of the base off square to allow the installation of the new sight mounting block. Then an alignment hole and a screw hole were drilled in the scope base to provide for mounting the sight base to the back of the block.

The wider base for the sight was needed to provide a place to drill and tap for the elevation screws which hold the sight to the base.

In the picture at the top of the next page, you can see that I used a screw to join the parts. An alignment pin was used to make sure the two parts stay plumb to one another. Silver brazing the parts would be an option. Because of time, I did not want to risk filling the dovetails in the scope base with braze.

Customized Talley Base with Redfield Peep.

Above you can see the finished, unblued, scope base with the new sight base attached. The scope base screw holes were altered for use with 8-40 screws at the client’s request.

Note on the above the sight base was positioned so it would not interfere with proper mounting of the scope base. Location of the elevation screws was selected to provide the maximum adjustability of the sight.

The complete installation is a tidy, compact set up that does not detract from the overall looks of the firearm. Such back-up sights are seldom used but if you’re on an expensive hunt and the scope gives out for any reason, it can be a life saver to have this alternative.

There are of course peep sights that will mount on the scope base in a quick-detach fashion. The advantage here is that there is no need to install the sight and there is less chance of its losing zero.

Front Sights

Instead of using cheap sight ramps on the muzzle of your rifle projects, consider using a banded ramp. They have a much more professional and finished look than a simple ramp. Banded sights appear to be more expensive and, for that reason alone, are popular when offered.

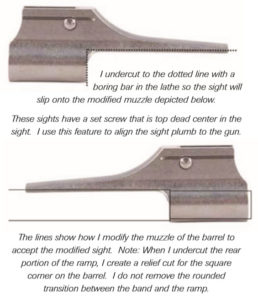

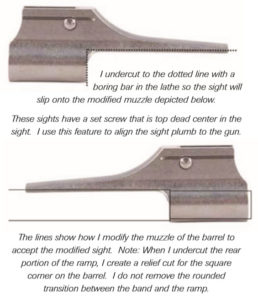

New England Custom Guns (NECG) offers four styles of banded ramps. There is really no reason to make your own with all the sizes and styles they offer. Pictured here is their “Masterpiece” banded ramp with a bead sight installed. This particular sight has a large flip up ivory bead for low light and close quarters shooting.

I order the banded ramp closest to the diameter of my barrel at the muzzle but always smaller than the muzzle diameter on the barrel. This allows us to fit the band to the barrel. Most guys bore the sight to final dimensions using a boring bar in the lathe.

Soldering these banded sights provides the best installation. The solder closes up any gaps and insures the base will not move under recoil. The most embarrassing thing for a gunsmith is to have a sight come off when the gun is fired.

The ramp pictured below has been soldered but not cleaned yet. Excess solder is removed with a fine file and finished off with sand paper.

If the barrel will be blued, you must get all the solder off the exterior as it will not color in the bluing bath.

Brownells “Hi-Force 44”™ solder is a perfect choice for sights. It flows and bonds freely at 640° F. It will also bond with stainless or chromoly steels. It contains 95% Cadmium and 5% Silver. This combination provides high tensile strength and is well suited for joints that are subject to stress and vibration.

My experience with this solder and bluing show that the caustic salts will slowly eat Hi-Force solder away, but much slower than lead/tin solder. Consequently, I normally remove the barrel from the bluing bath as soon as I have good solid color. Be sure to neutralize and boil out the parts too.

The question of accuracy comes up whenever we solder parts to the barrel. I have never had a problem. It’s important to keep the solder and flux out of the bore. Also, keep the heat down within the standard range for the solder. More is not better.

There is a wide variety of sight inserts available for these NECG banded ramps. Sight heights are available that will work with most any reasonable sight arrangement. The “Universal” bases even allow for some elevation adjustment with each blade. You can offer beads of various solid colors, fiber optics, brass or even sourdough pattern sights. Sight hoods are available as well for those ramps made to accept them.

Sourdough sight inserts can be filed to custom heights making them a great choice for custom load development.

Visit www.newenglandcustomgun.com to see the full range of ramps and sight inserts. NECG sights can be purchased through suppliers like Brownells and MidwayUSA. However, NECG offers more options than these distributors usually catalog so it pays to see if what you need is available direct.